Businesses that don’t use commercial GPS tracking systems to optimize operations are missing out on a list of advantages others use to get ahead. Studies show these systems can provide some major opportunities, like a 54% improvement in driver behavior or a 49% improvement in fuel savings.

These are advantages you can easily implement right now.

Let’s dive in.

A customer is on the phone; their delivery was supposed to arrive 30 minutes ago but still isn’t there. They want to know when it will arrive. You try calling the driver, but they don’t pick up. Your customer asks again. What do you tell them?

With a GPS tracking device, you know exactly how far away the driver is.

Many fleet tracking systems come with corresponding software that allows you to see precisely where a vehicle is, using your desktop or tablet.

With GPS trackers, you can tell customers exactly when to expect your driver to arrive.

Seeing where all of your fleet vehicles are at one time also helps you quickly determine who is closest to a particular location — like an unexpected pick-up. This can greatly improve your delivery services.

No more missed business opportunities because you were trying to figure out who could get there in time. You know — almost instantly — which driver you should dispatch.

More business with less hassle. Who doesn’t want that?

It’s the end of the day, and you’re about to head home when you hear that one of your trucks broke down.

Turns out it happened hours ago, but you’re only just now finding out about it. Now you have to figure out what to do with the shipment, get the truck repaired, and shift some schedules around; all while likely having to incur overtime costs.

You do what you can right now, but you’re worried some of it is going to have to wait until the next day.

With a GPS device installed in your fleet vehicles, you can get real-time alerts about vehicle issues the moment they occur; no matter where the vehicle is located.

That means being able to take care of problems immediately. It also gives you the chance to keep overtime costs down by planning schedules accordingly.

Lastly, with OBD tracker devices, maintenance personnel can look into the diagnostic trouble codes before the vehicle’s even in the shop; giving them a chance to order parts quicker and back on the road sooner.

You’re looking at your budget, and you can’t believe how much you’re spending on fuel and replacement parts every month. You don’t even want to look at how much you’ve paid in overtime to your maintenance staff.

With gas being your largest overhead cost, you know there’s a way to cut costs here, but getting it under control by yourself feels like an overwhelming task.

Recent studies show that businesses look at fuel savings as the biggest advantage of using GPS tracking.

Drivers tend to drive more cautiously when they know their driving habits are being monitored. Likewise, following the speed limit and limiting excessive mileage reduces wear and tear on the vehicle. This helps save money on your overall vehicle maintenance costs and reduce the likelihood of accidents- which aids your CSA scores.

Recent studies show that businesses look at fuel savings as the biggest advantage of using GPS tracking. `Every mile per hour over 50 mph burns 1.5% more fuel. Not to mention it wears down tires more quickly. So, having drivers keep their speed in check ensures that your fuel costs aren’t wasteful spending.

A GPS system also helps deter drivers from taking detours or unauthorized stops. It helps you spot driver behavior problems when they arise with the help of vehicle activity alerts. You are instantly notified when someone is off course.

Lastly, GPS tracking also allows your team to use route optimizers. Route optimizers are by far the best way for fleet managers to ensure their team takes the most efficient route and get more stops in every day.

Tractors, generators, trailers, forklifts, and skid steers are expensive pieces of equipment. And you rely on assets like these to get the job done.

With GPS technology, you never have to worry about whether it’s been stolen or where the equipment was last placed. A solid GPS tracking solution lets you know exactly where your equipment is at any point in time.

For added security, you can also geofence your worksites. Geofencing monitors any tracked equipment or vehicles that enter or leave the boundary you create. You get alerts sent right to your phone about anything that happens; even after-hours for immediate responses.

Furthermore, you can also easily see if equipment is stationed at the right job site. That way your crews can get right to work. It’s an easy way to help your team be more productive and the project more cost-effective.

Simply put, a GPS tracker is the best way to keep your equipment and worksite running safely and smoothly.

It’s a huge headache to keep track of all that paperwork. Keeping tabs on all the fuel logs, receipts, and state mileage information for taxes takes up a lot of your time.

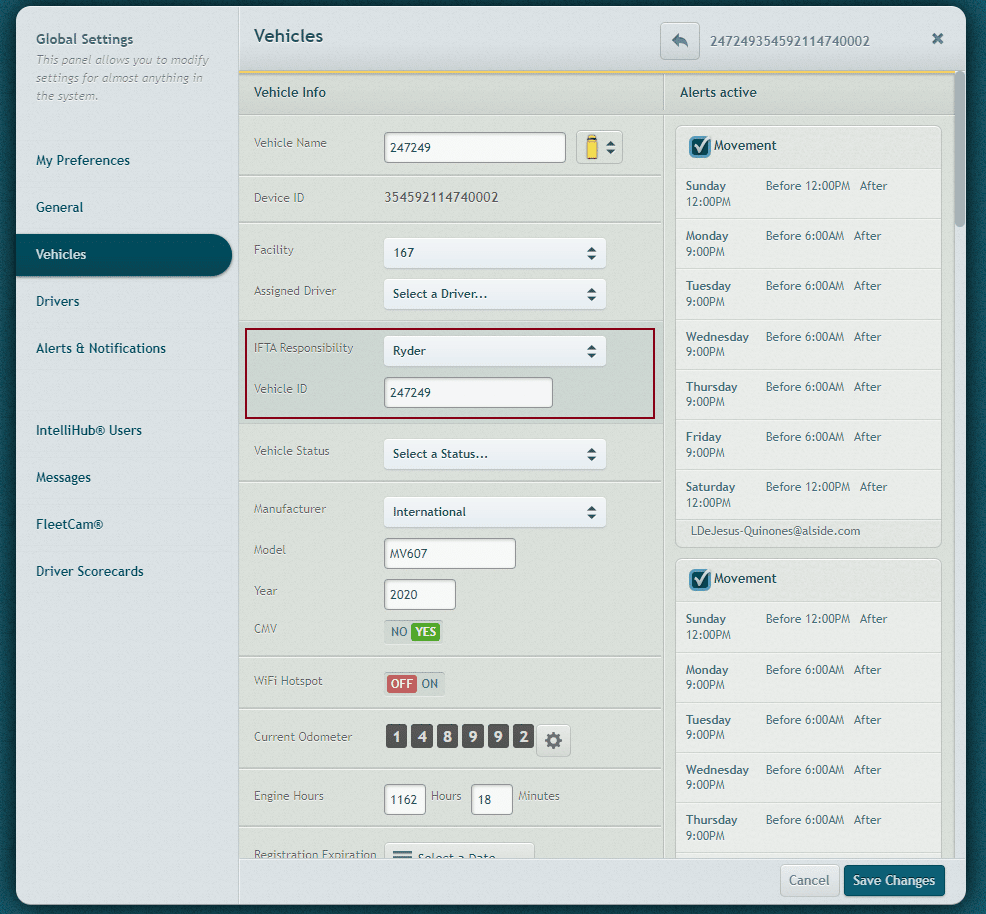

Fleet management software uses vehicle tracking and fuel purchase data to simplify the IFTA reporting process. It works by collecting and consolidating your fuel and state mileage data into a single report — automatically.

You can integrate your fuel cards and store digital copies of fuel receipts too.

Altogether, these programs make it easy to sort data for each vehicle and generate your reports; saving you time, money, and aspirin.

You want to reward your top-performing drivers and invest some money in training the ones that could use improvement. But unless you want to do a ride-along with every one of your drivers, you just aren’t going to be able to get the same sense of their driving habits as you would with the help of GPS tracking.

With a GPS device, you can tackle serious issues like speeding to spot your best and worst drivers.

A GPS tracking solution can help you focus your driver coaching efforts on the drivers who need it most. Saving you money on training costs. Not to mention, safer driving helps to improve CSA scores too.

GPS technology can make your job simpler.

Without a GPS tracking solution for your fleet, you’re likely leaving money on the table.

GPS data is the bedrock of so many fleet management solutions such as:

If you find yourself facing these issues day in and day out, it’s time to invest in a GPS tracking system.

GPS tracking is the foundation for the most helpful fleet management tools available. With a GPS tracker in your vehicles, you can make the most of route optimizers, dispatchers, driver coaching software, delivery alerts, geofencing, and more.

There is no one-size-fits-all answer to this question, as the best asset tracker for you will depend on your specific needs and preferences. However, some of the most popular asset tracker manufacturers on the market include ATrack, Bewhere, and Suntech. Each of these trackers has its own unique features, so be sure to check out this breakdown for help in deciding which one is right for you.

There are a number of GPS trackers on the market that are designed specifically for vehicular use. The best one for your needs will depend on your budget and what features you need.

If you’re looking for a low-cost option for personal use, the LandAirSea Sync is a good choice. It has basic features like real-time tracking, speed, and geofencing, and it’s priced at only $25.

If you’re looking for a more sophisticated business option, FleetCam offers a host of major benefits like real-time positioning data, dual-facing dashcam, AI driver behavior monitoring, in-cab alerts, live and historical video streaming, breadcrumb trails, and more.

GPS, or global positioning system, is a satellite navigation system that uses a network of satellites to triangulate your location. It can determine your location to within a few meters. GPS signals are sent from multiple satellites to the object being tracked. Each satellite talks with the other to compare distance to the object and determine an accurate location.

Psssst… Want to see how our GPS fleet tracking solutions can help you improve routing, dispatching, security, invoicing, and more?

Grab a free demo.

Do it.

Do it now.

Right down here. ⬇️

Updated Dec 28, 2022 – Original article authored by Ashley Preston

Recent Posts

Stay in Touch

Ready to make fleet management more manageable?

Schedule your demo today!